Cold Forming and Machining Services

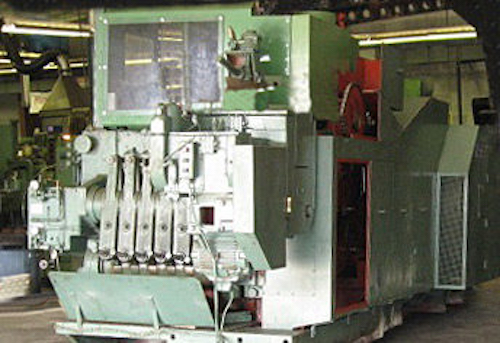

The foundation of EPS’s manufacturing originated with the cold forming process. This remains true, although an assortment of advanced machining equipment has been developed to complement and expand our capabilities. Our engineering experts can efficiently produce state of the art shapes in any application for virtually any industry.

Our cold forming production line includes high speed single station as well as large multi-station progressive equipment. On the machining side, EPS offers options that include lower cost conventional centers along with high speed CNC stations that are capable of tremendous precision.

To learn more about our manufacturing abilities, please see the table below or contact us today.

Cold Forming and Machining Service Capabilities:

- Cold Forming

Single Die Design

Multiple Die DesignProgressive Machine

Extrusions

- Machining

Pointing

Shaving

Drilling / Tapping

Trimming

Centerless Grinding

Shank Slotting

Head Slotting

Broaching

Swaging

Bending

BurnishingElectro Polishing

Mechanical Polishing

Machining

Roll Threading

Thread Forming

Patching

Plastic Retention

Head Painting

Poly Bagging

Custom Packaging

Light Assembly

- Materials

Aluminum

Brass

Copper

High Carbon Steel

Low Carbon SteelSilicon Bronze

Stainless Steel

Alloy Steel

Exotic Metals

- Finishes

Zinc

Black Oxide

Zinc Phosphate

Organic

Powder Metal

Zinc NickelZinc Iron

Mechanical Zinc

Tin Plating

ROHS Compliant

Exotic Finishes

Everlube

- Sealants / Adhesive

Loctite

FluorocarbonsTeflon

Epoxy

- Diameter

7/64 to 1 3/8 inch

3mm to 35mm metric

- Length

7 inches

177 mm metric

- Testing

Plating Thickness

Internal/External Go/No-Go

Tri-Micrometers

Pitch Micrometers

50X Comparators – 14″ Floor Comparator

Hydrogen Embrittlement

Drive-to-Strips

Tensile & Yield Testing

Micro Structure TestingSalt Spray Testing and Certification

Lot Control

PPAP’s, FEMA’s, 8-D’s

Gage R & R

Approval Drawings

SPC on Critical Dimensions

Tukon Hardness Testing

Special Gages for Production and Final Inspection

- Sorting

Laser

CameraEddy Current

Optical

- Additional Services

Heat Treating

Plating

Induction Hardening

- Production Volume

Prototype to Large Scale Production Volume Run

- Typical Lead Times

8 to 10 weeks

Rush Services Available